It is called CNC stone processing machine, which realizes the possibility to cut stone and polish stone edges with different types in one single machine. It helps much in improving the efficiency of finishing stone countertop for stone fabricator. With this machine, you will obviously save your labor cost at your stone work.

Item NO.:

YT5002Order(MOQ):

1Payment:

TTProduct Origin:

ChinaColor:

CustomizedShipping Port:

XiamenLead Time:

20-25 days after receiving depositWeight:

5 tonsCNC Stone Polishing Machine Quartz Countertop Different Edge Polishing Equipment Fast Flat Edge Finishing

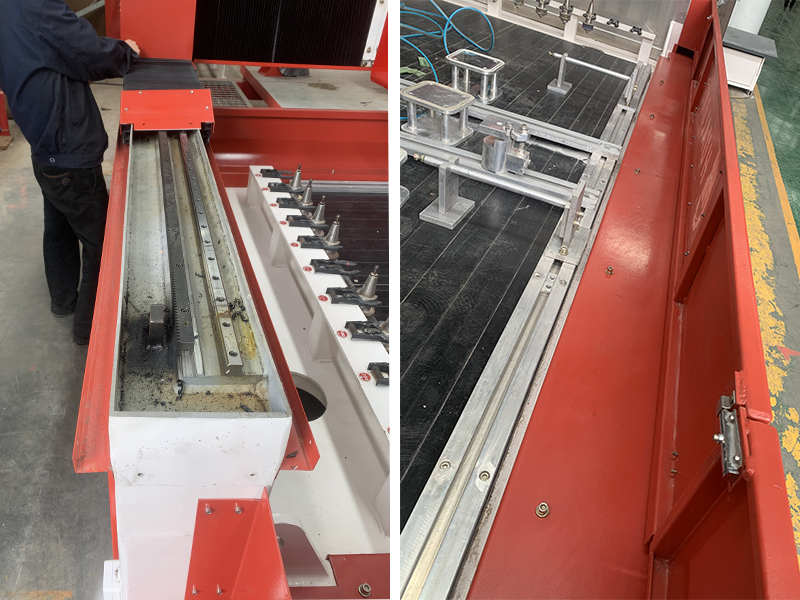

CNC Stone Processing Machine is a CNC milling centre designed for contouring, cutting, edge polishing and turning with three interpolated axis, offering users the possibility of multiple and complex machining operations which would otherwise require several machines. It's suitable for processing all kind of stone slab countertop, such as kithen countertop, bathroom countertop, cabinet countertop, bar counter, table, windowsill, door sets etc. With different shapes of polishing wheels, it can realize differnet countertop edge types, such as flat edge, ogee edge, bull nose edge, etc. It is not limited to one single countertop thickness, which could be customized with same effect.

Main Features

1) Possibility of using various shaped tools, drills, millers, polishers etc. with 20 positions.

2) Dust-proof and water-proof on three axis,protect the whole transmission system.

3) Crossbeam and carling adopt Taiwan's Hiwin linear guide to move, which ensures high precision of cutting and long life.

4) High speed and low noise.

5) High efficiency and low processing cost.

6) Equipped with Italy imported touch-screen and operation system to achieve friendly user interface operation.

Technical Data FOR TWO MODELS

| Name | Unit | MODEL CNC 3015 | MODEL CNC 3319 |

| Stroke (X-axis) | mm | 3040 | 3500 |

| Stroke (Y-axis) | mm | 1450 | 1950 |

| Stroke (Z-axis) | mm | 320 | 320 |

| Power | kw | 7.5 | 7.5 |

| Rotating speed | rmp | 0-8000 | 0-8000 |

| Tool holder model | BT | 40 | 40 |

| Gross weight | kg | 4000 | 5000 |

| Workbench dimensions | mm | 3000x1460 | 3300x1900 |

| Tool change positions | pcs | 12 | 20 |

Photos Reference:

Related other products: